Conveyor aluminium profiles are essential components in various industries, providing a robust and versatile solution for material handling systems. These profiles are designed to support conveyor systems, enhancing efficiency and productivity in manufacturing and logistics. In this article, we will explore the features, benefits, and applications of conveyor aluminium profiles, highlighting why they are a crucial investment for businesses.

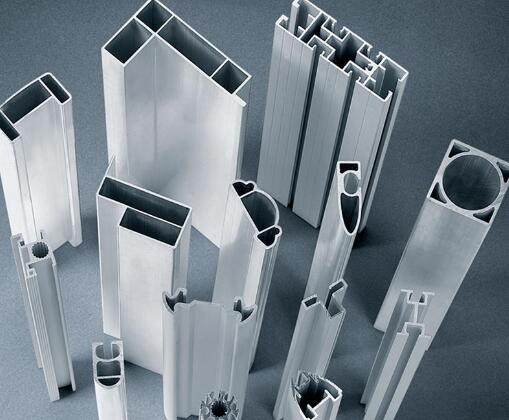

Conveyor aluminium profiles are extruded aluminum sections specifically designed for use in conveyor systems. They are lightweight yet strong, making them ideal for supporting various types of conveyor belts and components. The profiles can be easily customized to fit specific requirements, allowing for flexibility in design and application. Their modular nature enables quick assembly and disassembly, making them a popular choice for businesses looking to optimize their material handling processes.

One of the primary benefits of conveyor aluminium profiles is their lightweight nature. This characteristic makes them easy to handle and install, reducing labor costs and time during setup. Additionally, the lightweight design does not compromise strength, allowing these profiles to support heavy loads effectively.

Another significant advantage is the corrosion resistance of aluminium. Unlike steel, which can rust over time, aluminium profiles maintain their integrity even in harsh environments. This durability ensures a longer lifespan for the conveyor system, reducing maintenance costs and downtime.

The versatility of conveyor aluminium profiles is also noteworthy. They can be used in various applications, from simple conveyor systems to complex automated solutions. This adaptability makes them suitable for industries such as food and beverage, automotive, electronics, and packaging.

Conveyor aluminium profiles are widely used in different sectors due to their flexibility and strength. In manufacturing, they are often employed in assembly lines, where efficient material handling is crucial. The profiles can be configured to create custom conveyor systems that meet specific production needs.

In the logistics and warehousing industry, conveyor aluminium profiles facilitate the movement of goods, improving efficiency in sorting and distribution processes. Their modular design allows for easy reconfiguration, enabling businesses to adapt to changing demands quickly.

Additionally, conveyor aluminium profiles are used in packaging applications, where they support the movement of products through various stages of packaging. Their lightweight and durable nature ensures that they can handle the rigors of high-speed production lines.

Investing in conveyor aluminium profiles can lead to significant cost savings in the long run. Their durability and low maintenance requirements reduce the need for frequent replacements, while their lightweight design can lower energy costs associated with operating conveyor systems.

Moreover, aluminium is a sustainable material. It is 100% recyclable, making it an environmentally friendly choice for businesses looking to reduce their carbon footprint. By choosing conveyor aluminium profiles, companies can contribute to sustainability efforts while benefiting from a high-performance material handling solution.

In summary, conveyor aluminium profiles are essential for businesses seeking to enhance their material handling systems. Their lightweight, durable, and corrosion-resistant properties make them an ideal choice for various applications across multiple industries. By investing in conveyor aluminium profiles, companies can improve efficiency, reduce costs, and contribute to sustainability efforts. For more information or to explore options for conveyor aluminium profiles, please contact us to learn more about becoming a supplier of high-quality solutions.

Sign up to receive our newsletter and exclusive discounts and offters.